Description

High Performance Filtration Media

High Performance Filtration Media

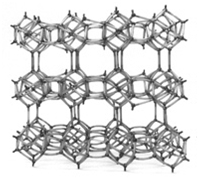

Filtration media, 3-5 micron filtration, single layer with expanded surface area, With high opal content for hardness & longevity, this is a high performance filtration media for all water and wastewater applications.

NextSand is a special zeolite based media, exclusively sourced from Western USA, and has been proven in demanding applications replacing standard multi-media and anthracite sand filter systems. Use NextSand to upgrade the performance of your pressure or gravity filter.

Supplied in 25 litre bags (0.88KGs/Litre), nextSand is easy to integrate into your filtration plant. Note sure how many bags to order? Send your enquiry to hello@waterform.co.nz and we will be glad to assist.

nextSand™ System Design Guide – Metric Edition

All values converted from the original US customary units for ease of design and operation in metric‐based regions.

1. Overview

nextSand is a high‑purity filtration media with high porosity (~27 m² g⁻¹) that enables higher solids loading and longer run times compared with conventional sand and multimedia beds. The standard design uses a 0.91 m bed depth (36″) with 50 % free‑board.

2. Service Flow Design

2.1 Recommended Filter‑Bed Flux Rates

| Bed Flux (m/h) | Operating mode | Typical application |

|---|---|---|

| 25 – 29 | Conservative | Pre‑RO/NF guard filtration, potable‑water SDI/NTU control |

| 34 – 39 | Moderate | General industrial polishing, cooling‑tower make‑up |

| 44 | High | Surface/ground water with low NTU/TSS where maximum throughput is needed |

2.2 Pressure Vessel Sizing & Service Flow Rates

(Metric equivalent of Table I — flow rates are m³ h⁻¹)

| Bed Flux (m/h) | Ø305 mm | Ø457 mm | Ø610 mm | Ø762 mm | Ø914 mm | Ø1219 mm | Ø1829 mm |

|---|---|---|---|---|---|---|---|

| 29 | 2.0 | 4.8 | 8.6 | 13.4 | 19.3 | 34.1 | 77.2 |

| 37 | 2.7 | 6.1 | 10.7 | 16.8 | 24.1 | 42.9 | 96.5 |

| 44 | 3.2 | 7.3 | 12.7 | 20.2 | 28.8 | 51.6 | 115.6 |

| 49 | 3.6 | 7.9 | 14.3 | 22.3 | 32.0 | 57.0 | 128.3 |

Bed volume and surface area for 0.91 m media depth

| Tank Ø | Bed Volume (m³) | Surface Area (m²) |

|---|---|---|

| 305 mm | 0.07 | 0.07 |

| 457 mm | 0.15 | 0.17 |

| 610 mm | 0.27 | 0.29 |

| 762 mm | 0.42 | 0.46 |

| 914 mm | 0.60 | 0.66 |

| 1,219 mm | 1.07 | 1.17 |

| 1,829 mm | 2.40 | 2.63 |

3. Backwash Design

3.1 Water‑Temperature / Viscosity Correction

Apply the factor in the table below to the calculated backwash flow to maintain ≈ 35 % bed expansion.

| Water Temperature (°C) | Correction Factor |

|---|---|

| 0 – 4 | 0.51 |

| 4 – 10 | 0.64 |

| 10 – 16 | 0.77 |

| 16 – 21 | 0.86 |

| 21 – 27 | 1.00 |

| 27 – 32 | 1.12 |

| 32 – 38 | 1.24 |

| 38 – 43 | 1.35 |

| 43 – 49 | 1.47 |

3.2 Backwash Flow Requirements

(Metric equivalent of Table III — flows are m³ h⁻¹, air at 6 psig ≈ 41 kPa(g))

| Tank Ø | Bed Backwash (m³/h)(35 % expansion) | Bed Backwash + Air (m³/h)(35 % expansion) | Air Scour Rate (m³/h)@6 psig |

|---|---|---|---|

| 305 mm | 3.6 | 2.3 | 4.1 |

| 457 mm | 8.2 | 5.0 | 9.2 |

| 610 mm | 14.3 | 8.6 | 15.8 |

| 762 mm | 22.3 | 14.3 | 25.0 |

| 914 mm | 31.8 | 22.3 | 36.2 |

| 1,219 mm | 57.2 | 31.8 | 64.2 |

| 1,829 mm | 128.3 | 77.0 | 144.2 |

Notes

- Base water up‑flow for hydraulic backwash ≈ 49 m h⁻¹ (20 gpm ft⁻²).

- When air scouring, reduce water flow to 60 % of the hydraulic‑only rate and inject air at ≈ 3 Nm³ h⁻¹ m⁻² of bed area (values shown above).

- Backwash duration: 5 – 6 min per cycle.

4. Design Formulae (Metric)

- Hydraulic backwash (m³ h⁻¹)

Q=49×A×CTQ = 49 × A × C_T

where A = bed surface area (m²), C_T = temperature correction factor. - Backwash with air scour (m³ h⁻¹)

Q=0.6×49×A×CTQ = 0.6 × 49 × A × C_T - Air scour rate (Nm³ h⁻¹)

Qair=3×AQ_\mathrm{{air}} = 3 × A

5. Quick Unit Conversions

| US unit | Metric equivalent |

|---|---|

| 1 US gpm | 0.227 m³ h⁻¹ |

| 1 ft² | 0.0929 m² |

| 1 ft³ | 0.0283 m³ |

| 1 ft | 0.3048 m |

| 1 psi | 6.895 kPa |

| (20 gpm ft⁻²) | 49 m h⁻¹ |

6. References & Assumptions

- Data sourced from “nextSand System Design Guide” (original US‑units specification).

- All conversions rounded to two significant figures for practical use.

- Verify local water temperatures and available backwash pressure before final design.

Reviews

There are no reviews yet.